Are you planning to buy an ERP system? There are a lot of manufacturing companies and distribution organization’s project teams are now considering an active ERP.

The requirements and reasons may vary but, likely, the technologies and processes are not entirely enough to manage costs, streamline operations and accommodate their growth.

Actual Requirements for Buying an ERP System

When the entire team and overall teams consider the entire capabilities of today’s new and modern ERP software and they are wise to take a clear look at whether their organizations are meeting their diminishing benefits from their legacy systems.

- The enterprise resource planning may be a victim sometimes and lead the end-of-life, where support is discontinued. There are different situations as another possible scenario involves the vendor as it depends on them as well by putting the product in “maintenance mode” with the same or limited updates.

- The old ERP system or software packages may no longer address the critical needs of today’s organization in areas of reporting and planning for overall efficiency.

- The scale is also another issue. Many times teams realize that they can’t scale their operations due to a legacy ERP system developed more than a decade ago. New markets and distribution channels are often found an outdated system and standalone spreadsheets which they are already using to run the company.

- Organizations depend on legacy products which are already limited due to a lack of mobile functionalities and analytics, CRM, and other applications that are needed in today’s environment

3 Pointers When Buying an ERP System

Pointer #1: Focus on Processes, Technology, and the people

To make the ERP projects successful it requires the most important work is done before the selection starts. It’s very much than dropping a new piece of software.

For an effective approach, remember, preparation starts at the top from C-Level professional support and buys an essential ERP and the other steps include developing a phase or we can say step by step strategy. This is also the high time to identify problem statements, holes, inefficiencies, and roadblocks in current business processes.

According to one survey about reviewed goals and expectations, whether or not they were achieved, and why.

- That survey found that the major and primary reasons for success include top management support and change management.

- Few Reasons for lack of implementation success and it includes inadequate project planning.

- While so many ERP implementations meet expectations in terms of schedule, budget, and ROI and leave the additional attainable returns on the table.

So again, putting Technology, people and processes first is the best step when the team is on the road to buying a new ERP system.

Pointer #2: Evaluate the Loss

Finalizing a new ERP system is not only complex but one of the most resource-intensive initiatives for a company.

One should consider the fields of loss that are underlying in such an effort by assessing and managing the most permanent loss related to cost overruns, project delays, and other issues. Typically in-house resources mainly don’t have large experience in evaluating this loss and therefore, find themselves reacting to lose and consequences after that it leads to problems in achieving expectations and meeting the goals.

The devotion of careful analysis of the different categories of loss that come with enterprise software selection and implementation? Spreading awareness of ERP risk categories will help project managers and stakeholders to take steps and address potential issues.

Pointer #3: Make ERP a priority with Comprehensive Planning

That survey found successful projects in ERP and invest more money and energy in understanding their business processes well in the first phase which is also called the preparation phase than they spend in the selection process.

This very new phase includes a planned analysis of ongoing processes and for future processes. It identifies the opportunities for changes and other outlines that are necessary to make any changes in management to achieve business expectations and it’s value.

Rather than focusing and converting the current state to a new ERP system, the project should focus on the technology to drive businesses various improvements.

Understanding this entire process is the key to success when evaluating a new ERP system. successful teams use a proven methodology with a team of high experts in manufacturing and distribution experts to ensure that the project emphasize is on preparation.

Final Thought

As your team considers and evaluates an ERP system, So you should consider how this enterprise can benefit from working with experts. We’ll leave you with this last reminder: be sure you take time to define the right processes, ensuring they are effectively used throughout the enterprise.

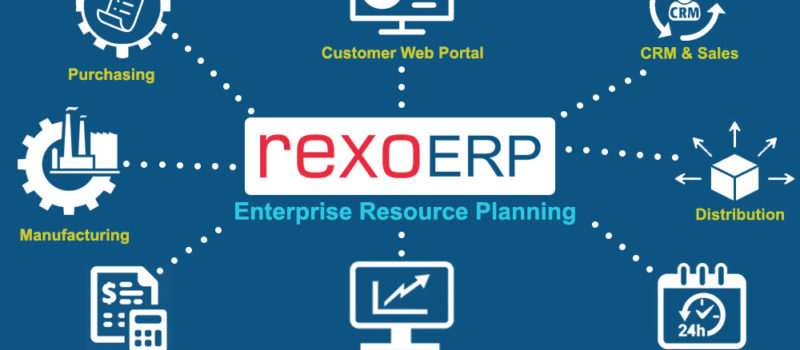

Rexo ERP for Manufacturing Companies is developed using Open source platforms and web-based server-side technologies. It is a platform that is independent as a system and runs on all operating systems. Rich role-based privilege system helps run your manufacturing processes smoothly and also enables a deep functional analysis of role-based tasks and performances. Flexible to accommodate new processes and even customizable to meet new requirements that may arise eventually in your business.

To know more about REXO ERP Software, please feel free to mail us on: info@techlene.com